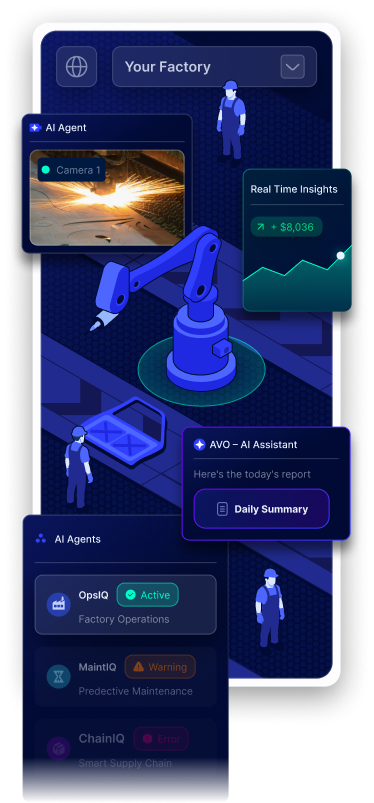

Factory Intelligence

Why Manufacturers Need Real-Time AI Intelligence

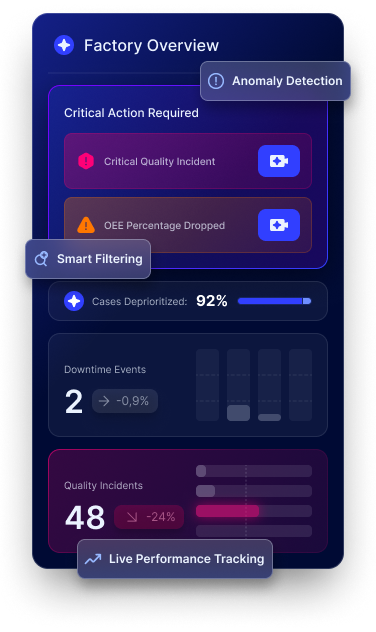

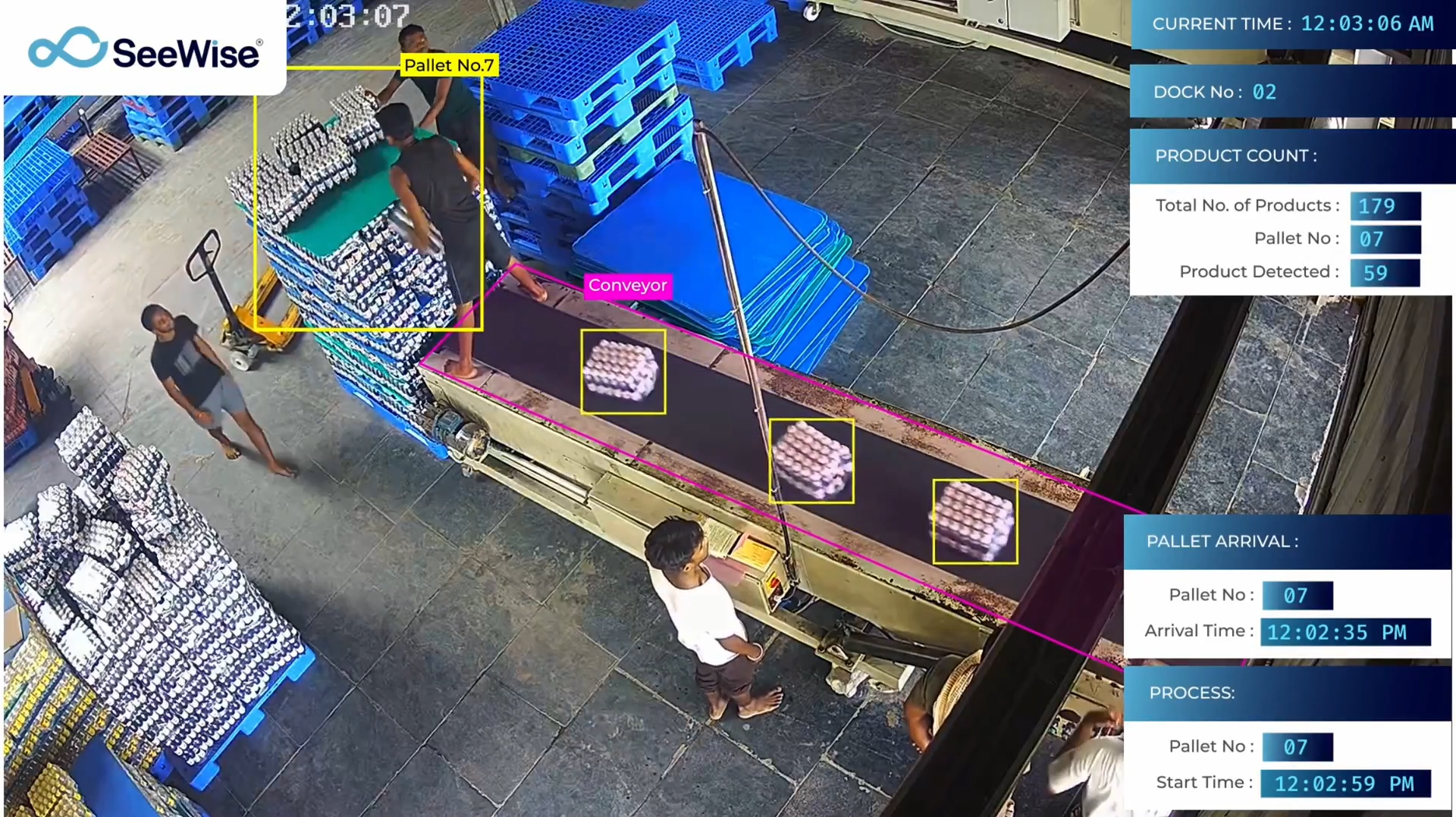

Catch Defects in Real Time

24x7 Vision AI cameras inspect every product, flagging quality, safety, and efficiency issues in real time.

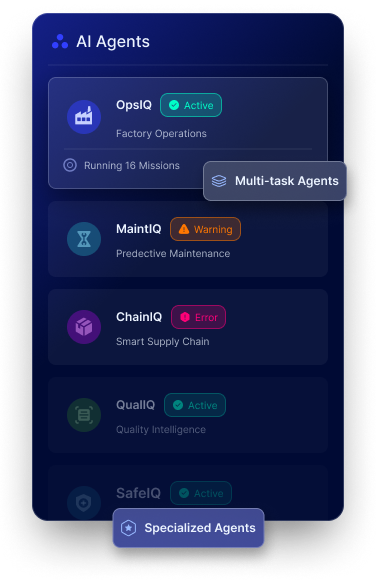

AI Workforce

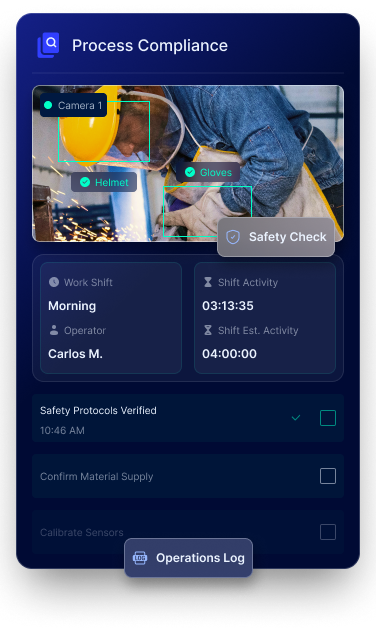

Keep Workers Safe and Compliant

AI tracks PPE usage, SOP adherence, and unsafe conditions across every shift to prevent incidents and ensure compliance.

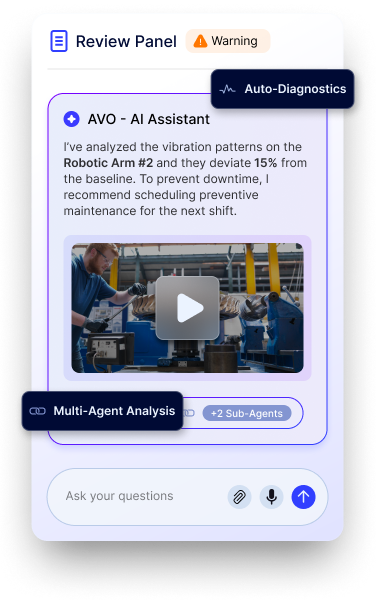

Predict and Prevent Every Downtime

Predictive monitoring detects early signs of equipment failure and triggers proactive maintenance to avoid costly downtime.

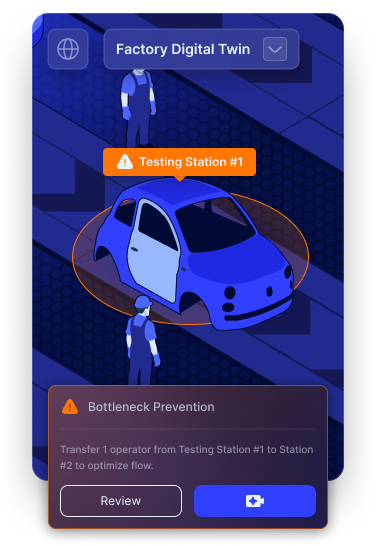

Make Every Shift More Efficient

AI-optimized workflows and labor allocation remove bottlenecks, balance workloads, and improve throughput.

Warehouse Optimization with 24×7 AI Observation

AI-powered monitoring combines camera feeds, equipment signals, and operational data to detect and correct issues as they happen.

Our Approach

AI-powered monitoring combines camera feeds, equipment signals, and operational data to detect and correct issues as they happen.

Assessment & Planning

- Current state analysis

- Use case prioritization

- ROI modeling

- Technical architecture

Pilot Deployment

- Deploy on 1-2 critical lines

- Core AI capabilities

- Baseline metrics

- Success criteria validation

Scale & Optimize

- Expand across facility

- Enterprise integration

- Advanced analytics

- Performance optimization

Continuous Improvement

- Model refinement

- New use cases

- 24/7 support

- Performance optimization

Where Manufacturing AI Delivers Immediate Impact